Presentation of a laboratory for the synthesis and study of melt-grown oxides

Last update 24 February 2023

This presentation comprises 438 slides or pages and is published by the library of the ETH Zurich / ETH Research collection via doi 10.3929/ethz-a-010817148:

external pagehttps://dx.doi.org/10.3929/ethz-a-010817148call_made

This link allows the download as pdf document or as ppsx type PowerPoint show with embedded videos.

Part 5 of the presentation describes a special concept to prepare polycrystalline sintered rods by using special pressing dies which are made of magnesia-stabilized zirconia. The pressing dies are used to press powder with a desired oxide composition into rectangular rods which are subsequently sintered at elevated temperature under an appropriate atmosphere. The sintered rods are processed in an optically heated floating zone melting furnace to synthesize melt-grown crystalline oxide materials.

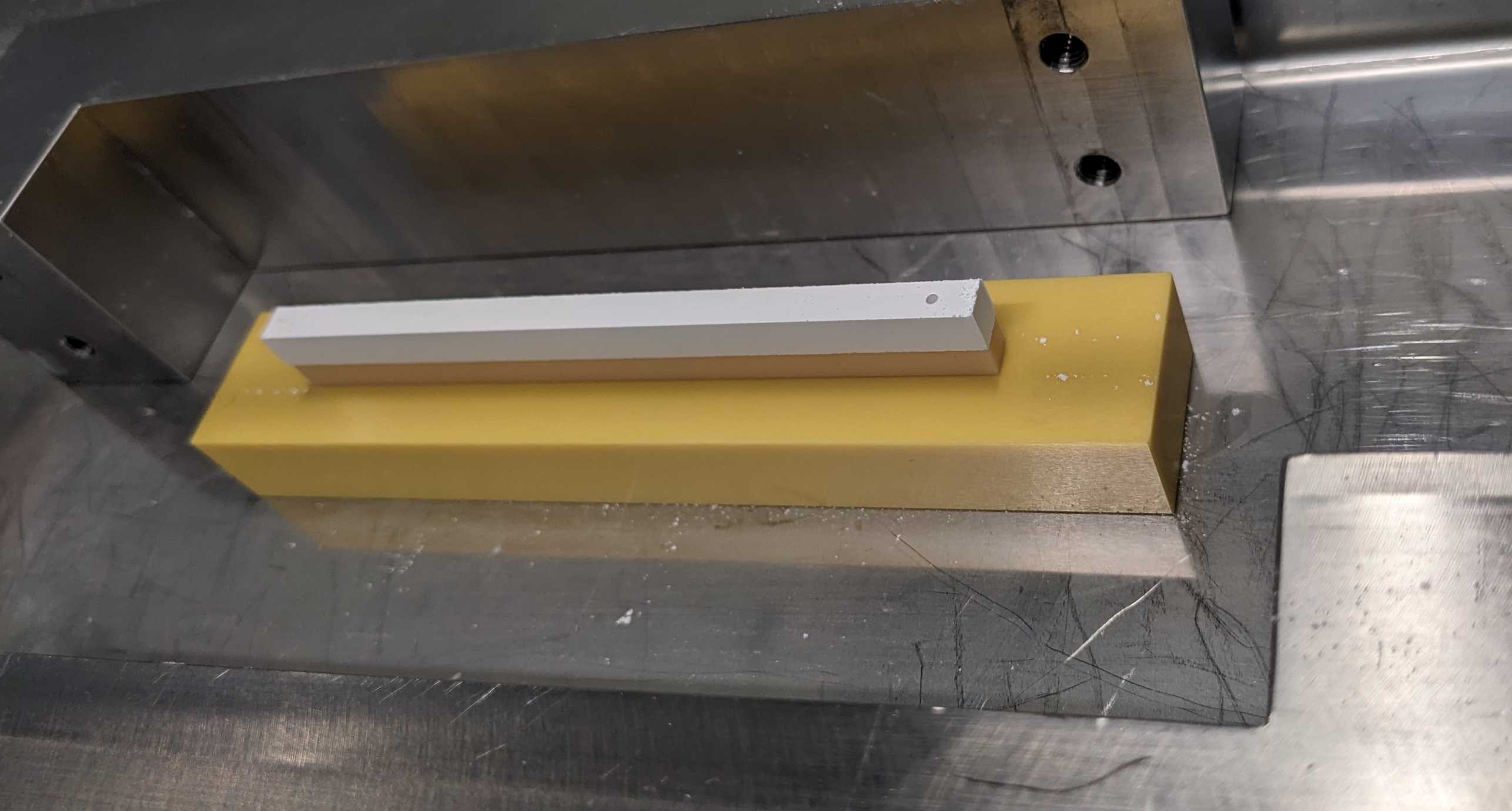

That pressing die, rod design, and rod preparation concept is also implemented by Darrell Schlom from the Cornell University as shown in the following pictures. The yellow components are likewise made of magnesia-stabilized zirconia and were manufactured by the company KYOCERA (formerly FRIATEC) in Mannheim in Germany. Components for two different sizes of pressing dies were produced, namely for the preparation of rectangular rods with dimensions 5 x 5 x 100 mm as well as 8 x 8 x 150 mm. The design and dimensions of the manufactured components are a result of several discussions between Darrell Schlom and Frank Lichtenberg. The following pictures were taken by Darrell Schlom in January 2023 at the “Leibniz-Institut für Kristallzüchtung” (IKZ) in Berlin in Germany.

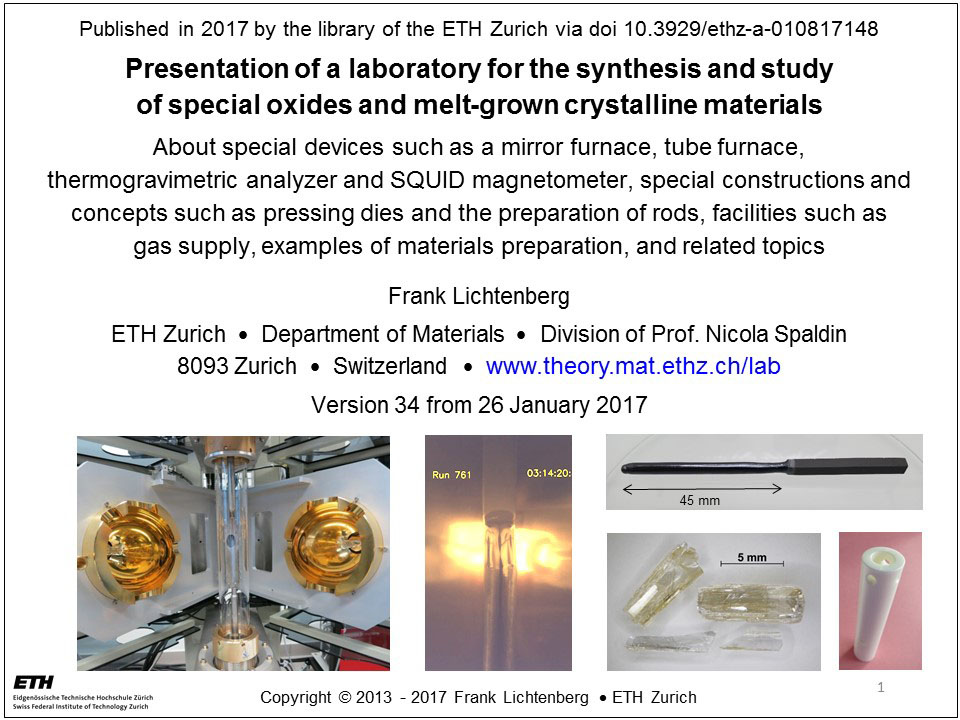

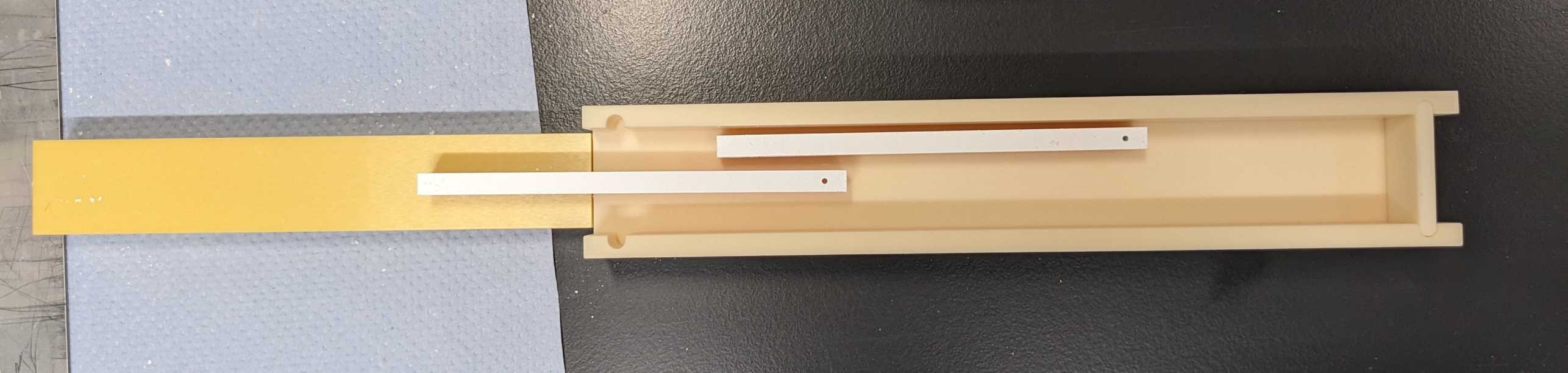

Top view of a pressing die which contains as-pressed powder with rectangular dimensions 5 x 5 x 100 mm.

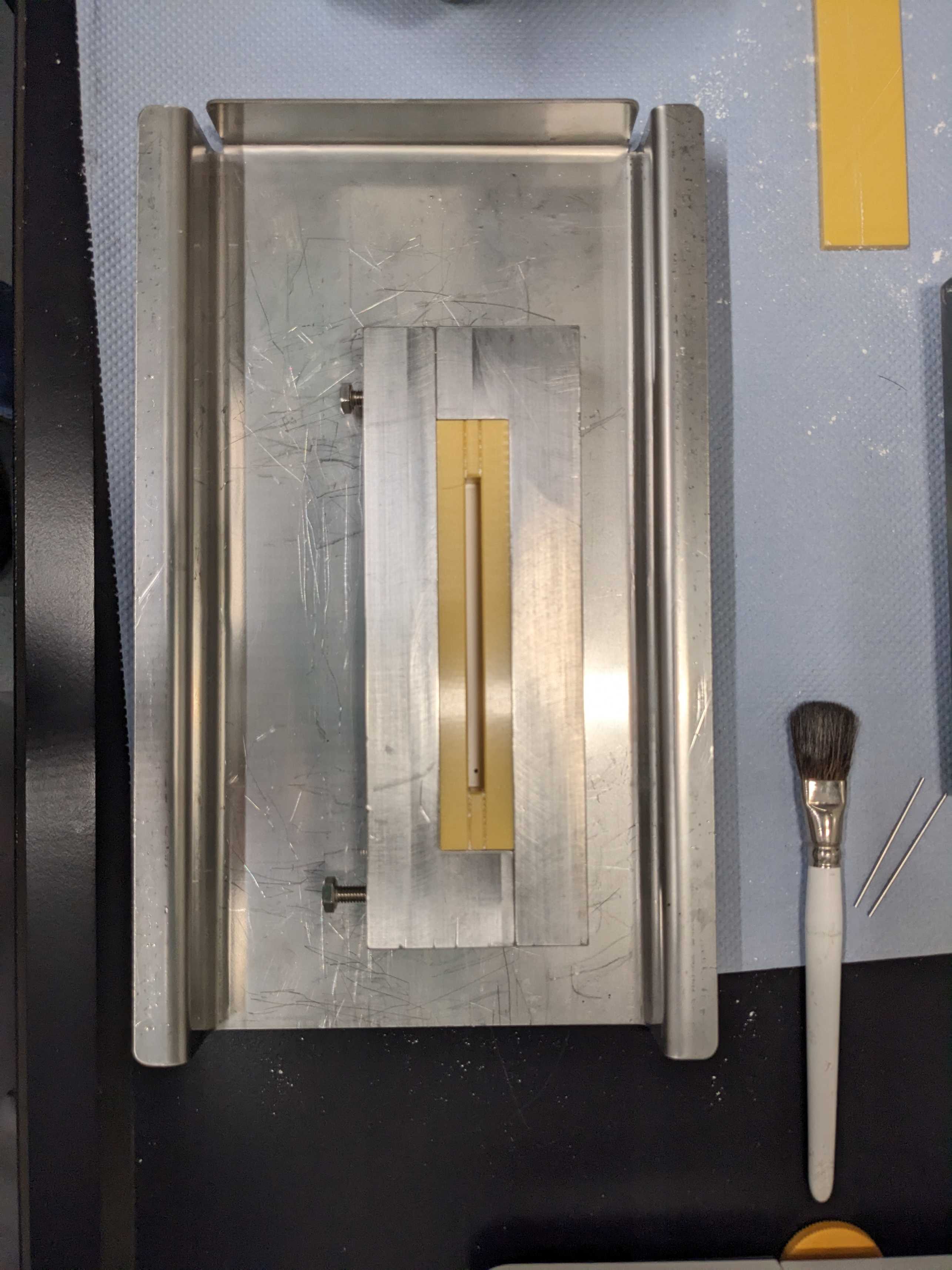

Completely assembled pressing die for the preparation of as-pressed rectangular rods with dimensions 5 x 5 x 100 mm. The yellow components are made of magnesia-stabilized zirconia.

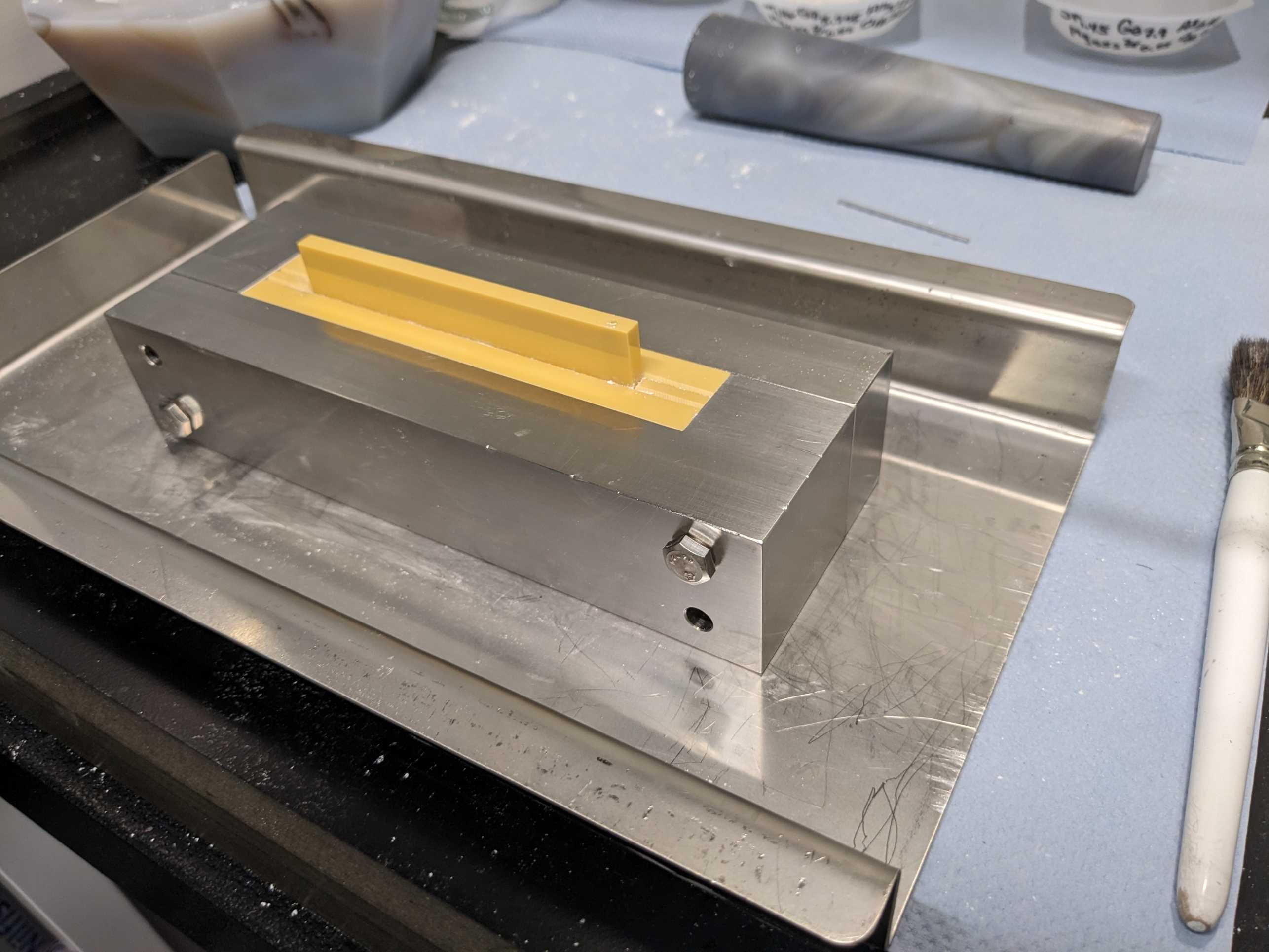

As-pressed rod with a continuous hole and dimensions 5 x 5 x 100 mm after removing the laterals. The as-pressed rod is located on a lower punch which is made of alumina. The available lower punches were likewise manufactured by the company KYOCERA.

Base plate of the pressing die (left), a custom-made alumina box (right), and two as-pressed rods. Each as-pressed rod is located on a lower punch made of alumina. To sinter the rods the alumina box can be placed into a furnace.